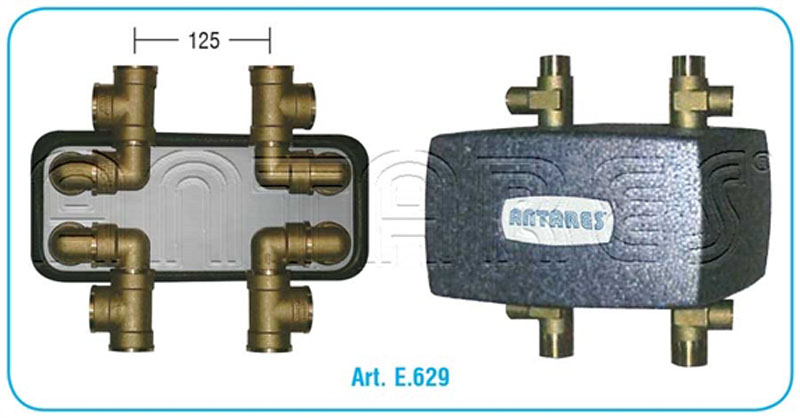

Prepared for direct connection with anticondensation biomass heat generators (Art E.627 on page..) and also for the control units for the lowering or mixing of temperature for radiant systems. (Art E.623 and E.625 on page..) It is composed of steel plate heat exchanger in the power listed, neccessary preassembled connection fittings and isolating shell. prepared for the connection of various accessories in corrispondence with the four ´T´ fittings - Distance between holes: 125mm.

Composed of the following components - Steel plate heat exchanger XXKWAT - Circulator 6mt in energy class ´A´Expansion vessle inserted or external equipment; - 3 bar safety valveCapillary manometer; -circuit feeding tap; - 4 intercepting ball valves; Dirt separator optional as accessory; automatic deareator; 4 steel flex 3/4´ extendible for connection.

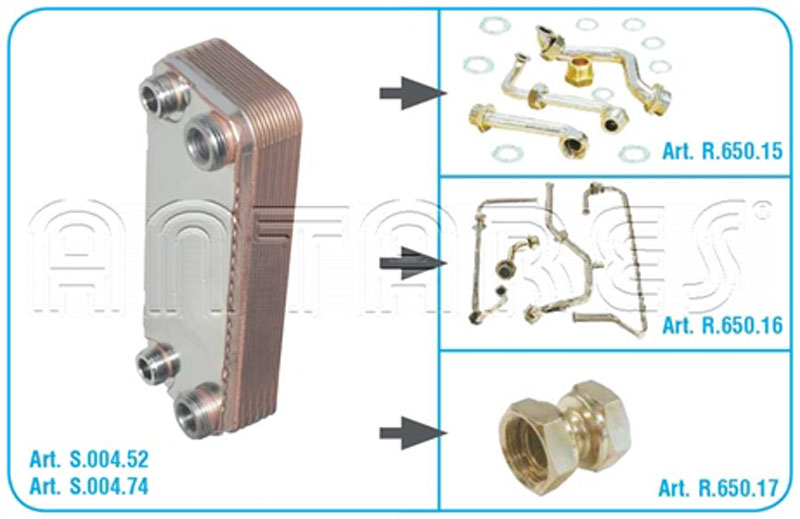

To equip boilers with production of hot sanitary water. Max pressure: 10bar. Absorption data listed below are calculated bearing in mind the following temp: primary circuit 80°/60°C - secondary circuit: 15/50°C. Compatible with boilers: VAILLANT VCW + KIT = 1; VAILLANT VMW + KIT = 2; CHAFFOTEUX + KIT = 3; PENSOTTI = 4; SARIGAS = 5; UNICAL = 6; ECOFLAM = 7; ATAG = 8; BROTJE = 9; RAVENHEAT = 10 OTHER BRANDS = 11; For the separation or splitting of circuits and other uses. = 12

Surface exchange for every plate: 0,023 m2 x number of plates . Water amount for every channel: 0,05 lt. x number of plate - max pressure 30barComplanar fittings : 2 x 3/4´M. + 2 x 3/4´M Opposite fittings. On one side:2 x 3/4´ M. On the other side 2 x 3/4´M. + 2 x 3/4´F. For S.008 (shells) see S.017

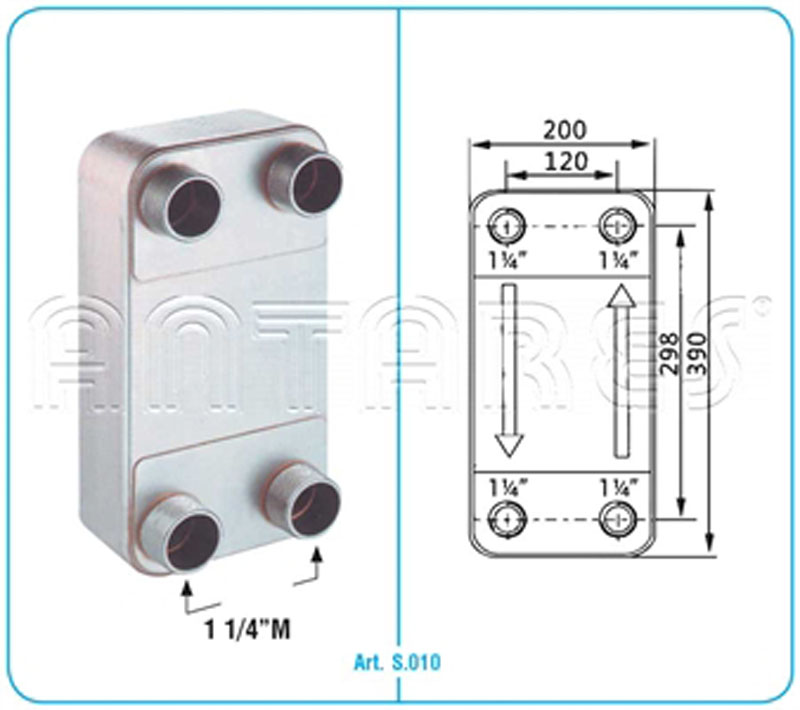

surface exchange for every plate 0.063m3 x number of plates - 2 - Amount of water contained per channel: 0.15lt x number of plates - 1 - max pressure 30bar - Especially indicated for combining open circuits (solid fuel boilers) with closed circuits (mod. In steel aisi 304)and for heating pools (mod. In steel aisi 316).