To equip boilers with production of hot sanitary water. Max pressure: 10bar. Absorption data listed below are calculated bearing in mind the following temp: primary circuit 80°/60°C - secondary circuit: 15/50°C. Compatible with boilers: VAILLANT VCW + KIT = 1; VAILLANT VMW + KIT = 2; CHAFFOTEUX + KIT = 3; PENSOTTI = 4; SARIGAS = 5; UNICAL = 6; ECOFLAM = 7; ATAG = 8; BROTJE = 9; RAVENHEAT = 10 OTHER BRANDS = 11; For the separation or splitting of circuits and other uses. = 12

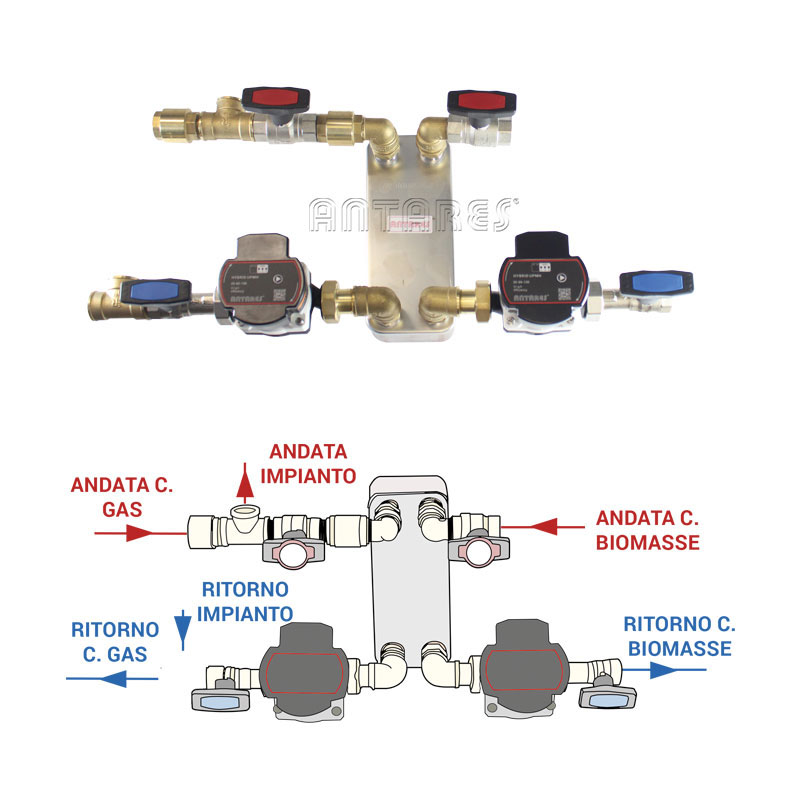

Composed of the following components - Steel plate heat exchanger XXKWAT - Circulator 6mt in energy class ´A´Expansion vessle inserted or external equipment; - 3 bar safety valveCapillary manometer; -circuit feeding tap; - 4 intercepting ball valves; Dirt separator optional as accessory; automatic deareator; 4 steel flex 3/4´ extendible for connection.

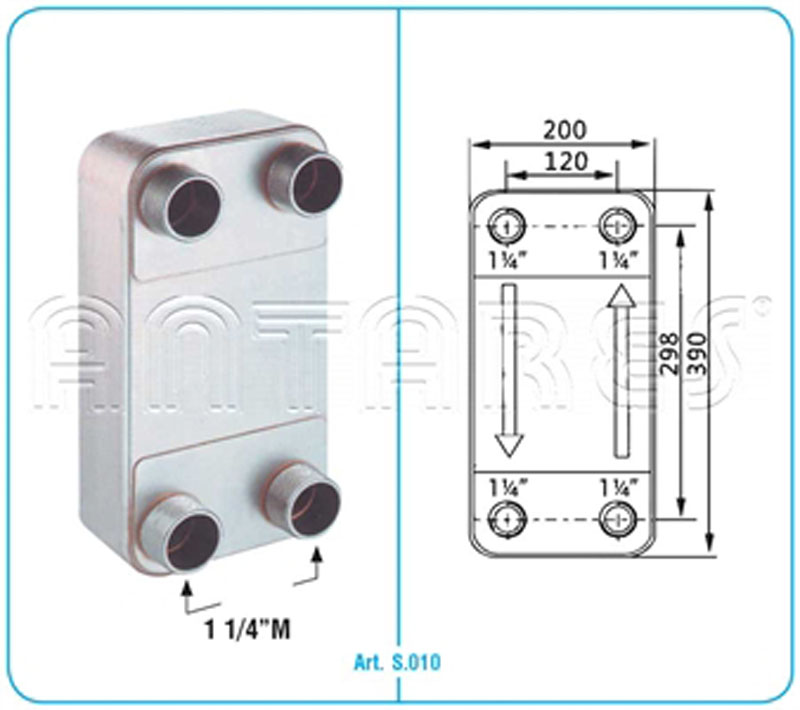

Made with stainless steel plates AISI 316 and gaskets in NBR. Connections with barrels nipples in stainless steel 1 1/4´ M. Also suitable for swimming pools (chlorinated water) and for the passage of water with glycol antifreeze. Allows the production of hot water in the measures specified below based on the following temperatures: Primary circuit 70°C min, Secondary circuit with inlets of 15°C and outlets of 50°C (Delta-t 35°C). Technical sheet may be downloaded from our website in pdf file - In order to have a greater potential it is possible to combine them with parallel connections. surface thermal exchange for every plate m2= 0.034(per plate) max working pressure 10 bar – volume contained for every channel 0.19(per plate).

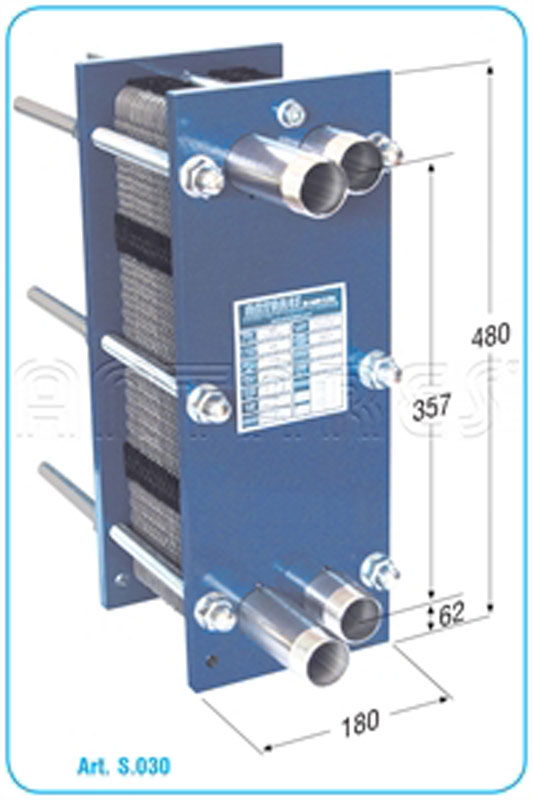

Made with stainless steel plates AISI 316 and gaskets in NBR. Connections with barrels nipples in stainless steel 2´ M. Also suitable for swimming pools (chlorinated water) and for the passage of water with glycol antifreeze. Allows the production of hot water in the measures specified below based on the following temperatures: Primary circuit 70°C min, Secondary circuit with inlets of 15°C and outlets of 50°C (Delta-t 35°C). Technical sheet may be downloaded from our website in pdf file - In order to have a greater potential it is possible to combine them with parallel connections. surface thermal exchange for every plate m2= 0.063(per plate) max working pressure 10 bar – volume contained for every channel 0.24(per plate).

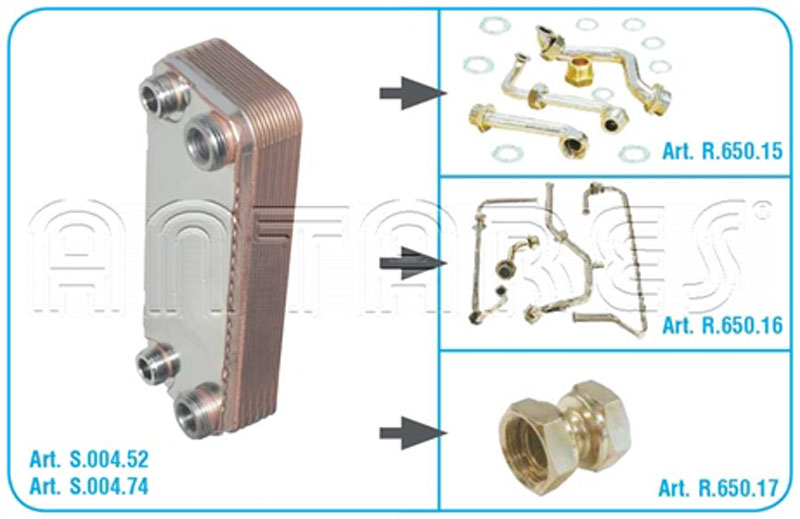

Surface exchange for every plate: 0,023 m2 x number of plates . Water amount for every channel: 0,05 lt. x number of plate - max pressure 30barComplanar fittings : 2 x 3/4´M. + 2 x 3/4´M Opposite fittings. On one side:2 x 3/4´ M. On the other side 2 x 3/4´M. + 2 x 3/4´F. For S.008 (shells) see S.017

Available with or without 3 way thermostatic mixing valve, for controlling temperature of hot sanitary water. Conn: heating system 1´M - distance 125 - max pressure 10 bar.

Equipped with stainless steel heat exchanger AISI 304 (Art S.009) 2 pumps in energy class ´A´ (Art P.064.6) 2 ball valves (Art E.465), 2 ball valves with thermometer (Art E.478) and 2 check valves (Art A.010.10) Max working temp. 99°C Max working pressure 15 bar.

surface exchange for every plate 0.063m3 x number of plates - 2 - Amount of water contained per channel: 0.15lt x number of plates - 1 - max pressure 30bar - Especially indicated for combining open circuits (solid fuel boilers) with closed circuits (mod. In steel aisi 304)and for heating pools (mod. In steel aisi 316).